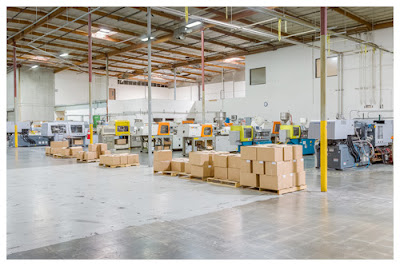

The Best Injection Molding Company is a plastic product factory specializing in the design, manufacturing, and assembly of plastic parts for the custom fabrication of various products. Our expertise includes rapid prototyping services utilizing our in-house equipment, as well as traditional mold-making processes utilizing plastic tooling materials. From the beginning, we have been passionate about developing innovative injection molds and manufacturing solutions for businesses. We're committed to helping our clients succeed in their markets by offering high-quality products and world-class customer service.

|

| Best Injection Molding Company |

Injection Molding Leverages Repetition & Consistency

Injection molding is a very reliable process. That is, the second portion you make will be nearly identical to the first, etc. When it comes to maintaining brand loyalty and part reliability in high-volume manufacturing, this offers a lot.

What Is The Downside To Injection Molding?

Because of the large industrial scale required in injection molding, even small errors can have significant financial and logistical ramifications. While the margin of error is small, the consequences are significant.

High-Quality Injection Molding is a good method for large-scale industrial production. It's also handy for finished prototypes that are being tested by consumers and/or product testing. For more information, visit us at: www.nubsplasticsinc.com.

Comments

Post a Comment