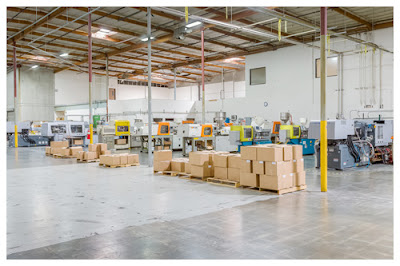

P lastic manufacturing has long been a backbone of modern industry, supporting sectors ranging from healthcare and automotive to consumer goods and electronics. Today, Plastic Manufacturing in the United States is undergoing a powerful transformation, driven largely by advanced injection molding technology. These innovations are helping manufacturers achieve higher product quality, tighter tolerances, faster production cycles, and greater sustainability than ever before. At the heart of this evolution are injection molding processes that combine automation, data-driven controls, and precision tooling. As competition increases and customer expectations rise, companies across the U.S. are investing in smarter manufacturing solutions to stay ahead. The Role of Injection Molding in Modern Plastic Manufacturing Injection molding is one of the most widely used processes in plastic manufacturing. It involves melting plastic resin and injecting it into a mold cavity, where it cools and sol...

Consider a few of the benefits of plastic Injection Molding Manufacturer's parts, and you might discover a convincing argument to switch.

|

| Injection Molding Manufacturer's |

A design that is flexible

Metal components for a range of uses can be made to order, but they don't have nearly as many design options as molded plastic components.

Cosmetic Enhancements

By employing plastic injection molded components, you may get a look. They are still functional even after being molded into a range of colors, shapes, and sizes.

Higher Productivity

Injection molding of metal is less exact than that of plastic. It's possible that the final metal products aren't the right size or shape.

Cost-cutting

Producing and purchasing plastic parts is less expensive, and customization is easier and less expensive. To create parts that are precisely the size and shape you need, a manufacturer merely needs to program the dimensions into the injection machine.

Furthermore, High-Quality Injection Molding says that the time and money saved by eliminating the need for reworking, grinding, sealant application, designing, and product testing saves even more. Please contact us at sales@nubsplastics.com or 760-598-2525 for additional information.

Comments

Post a Comment