In modern manufacturing, injection molding has emerged as a cornerstone technique for producing intricate and precise parts with efficiency & accuracy. From everyday consumer products to complex industrial components, Injection Molding Manufacturers play a pivotal role in shaping various industries. In this blog post, we'll delve into the realm of injection molding and explore the significance of high-quality manufacturers in delivering top-notch results.Injection Molding Manufacturers

Understanding Injection Molding: A Brief Overview

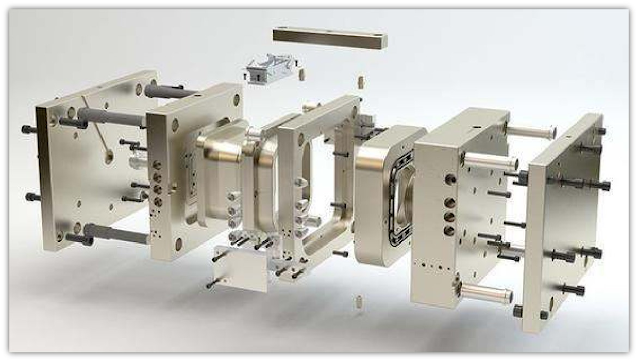

Injection molding is a manufacturing process that involves injecting molten material, often plastic polymers, into a mold cavity. Once the material solidifies, the mold is opened, and the final product is ejected. This process is known for its versatility, enabling the production of everything from tiny gears to large car panels with remarkable consistency and precision.

The Role of Manufacturers in Ensuring Quality

While injection molding offers numerous advantages, the quality of the end product heavily depends on the capabilities and expertise of the manufacturers. High quality injection molding manufacturers go beyond just operating machines; they bring a wealth of experience, technology, and dedication to the table.

|

High Quality Injection Molding

Key Characteristics of High Quality Injection Molding Manufacturers

- Advanced Technology: Reputable manufacturers invest in state-of-the-art machinery and equipment. They stay updated with the latest technological advancements in injection molding, allowing them to deliver products that meet stringent quality standards.

- Material Knowledge: Different materials behave differently during the injection molding process. A reliable manufacturer possesses in-depth knowledge about various materials, their properties, and how to optimize the molding process for each one.

- Design Expertise: The design of the mold and the part being produced significantly impact the outcome. Seasoned manufacturers have skilled design teams that create molds tailored to the specifications, ensuring minimal defects and optimal product performance.

- Quality Control: Rigorous quality control measures are a hallmark of high-quality manufacturers. They employ thorough testing and inspection protocols throughout the manufacturing process to identify and rectify any defects or deviations.

- Efficiency & Scalability: A valued manufacturer cares about both providing high-quality items and doing so effectively. They streamline operations to cut down on waste, energy use, and manufacturing time, making them a trustworthy partner for both small & big projects.

- Collaboration & Communication: Clear communication is vital in manufacturing. High Quality Injection Molding manufacturers work closely with their clients, involving them in key decisions and providing regular updates on the production progress.

Benefits of Choosing a High Quality Injection Molding Manufacturer

- Superior Products: High quality manufacturers deliver products that meet or exceed specifications, leading to better performance and durability.

- Cost-Effectiveness: While the initial costs might be slightly higher, the long-term benefits of fewer defects, less downtime, and reduced maintenance costs far outweigh the investment.

- Faster Time-to-Market: Efficient processes and fewer defects mean quicker production cycles, allowing your products to reach the market faster.

- Long-Term Partnership: Partnering with a reliable manufacturer fosters a long-term relationship built on trust, which can lead to collaborative innovation and shared success.

In Conclusion

Manufacturers of injection molding play a critical part in defining the products that make up our world. High-quality manufacturers ensure that the items created are of the greatest level by bringing knowledge, innovation, and dedication to the table. Prioritize quality, experience, and a track record when looking for an injection molding partner because these features are essential to a productive & successful collaboration. The success and quality of your finished product may ultimately depend on the manufacturer you select.

Comments

Post a Comment